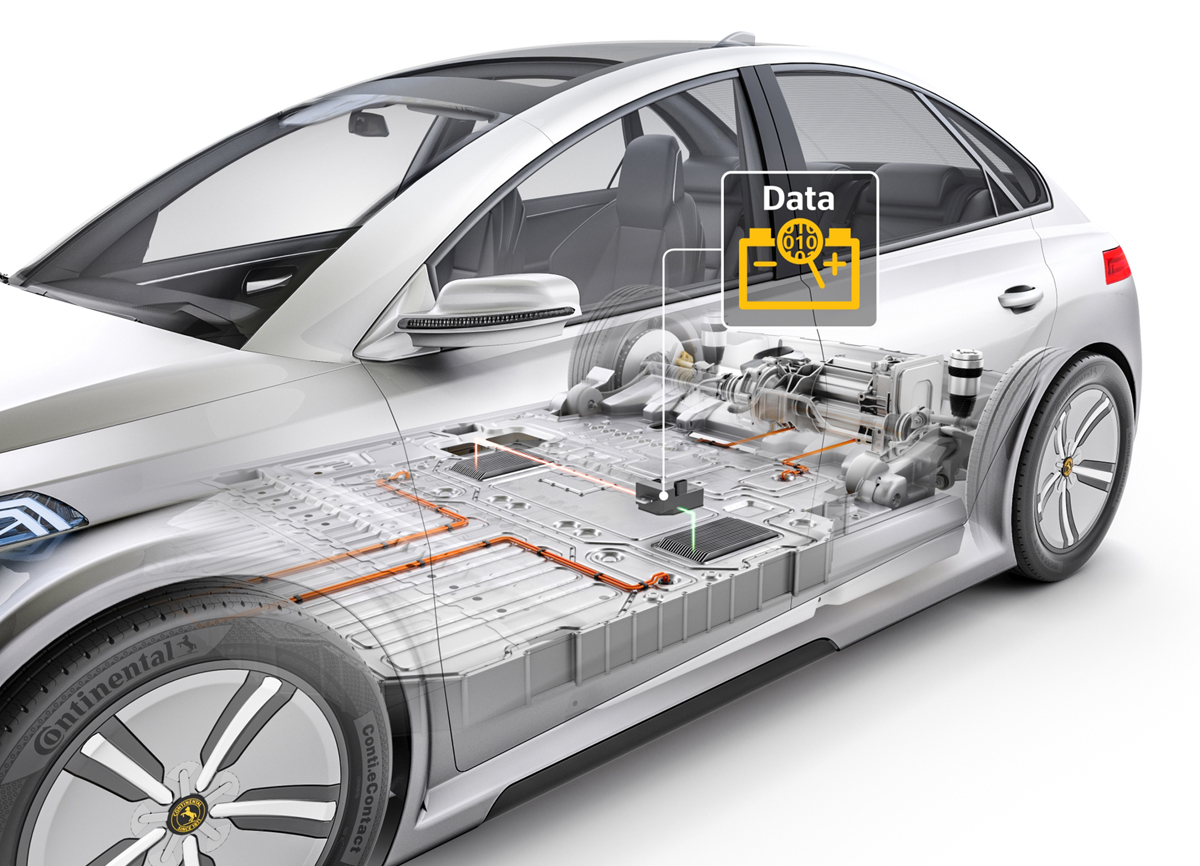

The current sensor module provides current and temperature information to ensure the safety and longevity of the high voltage battery. (Photo: Continental)

Electric mobility needs many sensors. According to Continental, the range is being expanded to include sensors developed specifically for electric mobility and to support both vehicle and electrical safety. The resource is currently building the reference With current sensing module and battery impact detection. The current sensor is intended to provide current and temperature information to ensure the safety and longevity of the high voltage battery. Shock Detection provides half the protection of the bottom light compared to traditional metal systems.

Considering that the battery is the most expensive component of an electric vehicle, the current sensing module was developed not only to protect the battery from overcurrent, but also to preserve the battery’s properties by limiting the effects of Continental’s advance. In the field of sensors, the supplier is also involved in industrial applications And just last summer it announced that it would boost efficiencies with Israeli startup Feelit specializing in high-sensitivity sensors.

The new car sensor module measures current and records temperature at the same time – both values that are important as input variables for battery management. The current sensing module is integrated either into a so-called battery disconnect module or into the battery itself, and is intended to provide two essential pieces of information for the reliable battery protection function and range monitoring. The unit is designed as a dual channel sensor that integrates shunt and hall technique It measures current independently in one compact unit. The supplier has announced that it will begin production of the all-new existing sensor module this year.

According to Horst Gering, Program Manager at Negative, charging a battery quickly is a compromise between keeping the battery healthy and reducing charging time. Safety and sensors. It is better to do this on the basis of accurate data. The measured current of the current sensing unit can be calibrated up to 2,000 amperes with an accuracy of less than ±1 percent on the shunt channel and ±3 percent on the Hall channel, at temperatures from -40°C to 125°C. Both current measurement technologies provide complete galvanic isolation.

Impact detection replaces the trained eye

Battery impact detection combined with the lightweight chassis recognizes underside penetration and warns the driver if it is necessary to visit the workshop. This is to rid them of the difficult decision of whether high speed collision or low speed ground contact could damage the battery. According to Continental, the system can save up to 50 percent in weight compared to existing metal underbody protection.

The pressure sensing satellites used to detect the impact of the battery come from the Pedestrian Protection System PPS pSAT, which has been in series production for more than ten years and is used in millions of vehicles. “In addition, battery impact detection identifies the area of damage, allowing battery management to drain cells in that area to avoid the risk of fireJohannes Klemm, general manager of Continental Safety Engineering International in Alzenau explains. The system signal can also be used to trigger a fast-acting active damping system, according to Continental, to temporarily increase the underbody height and mitigate damage.

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Samsung Quantum Dot TV: Art meets technology

Pitch: €56m for energy startup Reverion

Plastoplan: Plastics for Energy Transition