Industrial ultrasonic machines provide effective and gentle surface cleaning as well as precise material delivery using ultrasonic vibrations. In addition, they play a crucial role in process monitoring and quality control in various manufacturing processes.

Ultrasound technology has become an integral part of various industries in recent years. Originally known for their medical applications such as imaging and diagnostics, industrial ultrasonic machines have gained widespread acceptance in areas such as cleaning, welding and process control. In this blog post, we will examine the purpose of these sophisticated machines in more detail and examine their role in various industries.

Cleaning: Effective and gentle cleaning of surfaces

One of the most important applications of industrial ultrasonic machines is in the field of… Industrial cleaning systems. These machines use ultrasonic vibrations to remove dirt, oil, grease and other contaminants from surfaces without the use of abrasives or harsh chemicals. This makes it ideal for cleaning sensitive parts such as electronic components, optical components or delicate metal parts. Ultrasonic waves create tiny cavitation bubbles in the cleaning medium, which, when burst, release intense cleaning power and can reach even hard-to-reach areas. This means that industrial ultrasonic machines enable comprehensive and effective cleaning in various production processes.

Welding: precise connection of materials

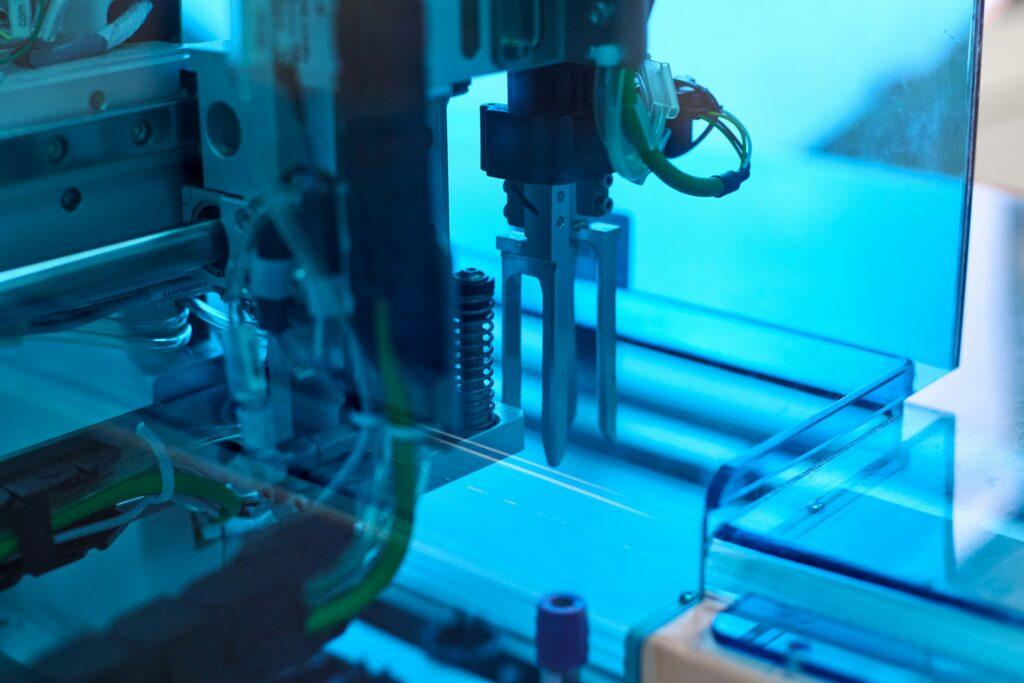

There is another important field of application of industrial ultrasonic machines Plastic welding And other materials. These machines use ultrasonic vibrations to create local heating and melting on the surfaces to be joined. By specifically controlling the ultrasonic energy, materials can be welded together without the need for additional adhesives or welding agents. This enables fast, accurate and clean contact, which is widely used in various industries, from automotive to packaging. Ultrasonic welding machines also offer the advantage of low thermal pressure, which is especially important for sensitive materials.

Process control: precise measurement and monitoring

In addition to cleaning and welding, industrial ultrasonic machines also play a crucial role in process monitoring and quality control. Ultrasonic devices are used in many manufacturing processes to accurately measure material thickness, density, homogeneity, and other physical properties. For example, ultrasonic thickness gauges are used in metalworking to monitor the thickness of sheets or tubes to ensure they meet the required specifications. In addition, ultrasonic testing devices are used to detect material defects such as cracks or air pockets to ensure the quality and safety of the products.

Conclusion

Industrial ultrasound machines have proven to be versatile tools that extend far beyond their original medical applications. From cleaning sensitive parts to precisely bonding materials and monitoring manufacturing processes, they play a crucial role in various industries. Their ability to work efficiently, courteously and accurately makes them indispensable tools for modern manufacturing and production environments.

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Technology: Kick with AI: How AI is transforming football

Researchers are developing 3D printing technology for ultra-thin multilayer tube structures

Meta: New AI-powered advertising tools for more success in the reels