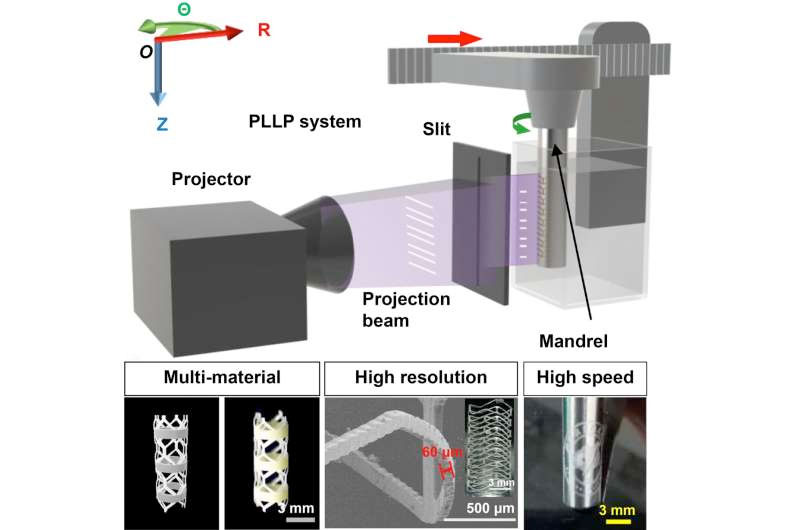

Scientists at Beihang University have developed a new 3D printing technology that can produce multilayer tube structures made of various materials with a wall thickness of just 50 micrometers and a detail resolution of up to 10 micrometers. The results were published in the International Journal of Extreme Manufacturing published.

This technology, called polar coordinate line photoprocessing production (PLLP), could be used in the future for rapid customization of tubular implants and manufacturing of tubular components in fields such as dentistry, aerospace, and more.

“Soft and ultra-thin tubular structures are widely used in biomedical engineering,” explains Professor Jibo Lee, corresponding author of the study. “However, producing them using traditional 3D printing systems based on Cartesian coordinates is very difficult. Therefore, we designed our platform to be cylindrical and built in polar coordinates.

PLLP technology uses a rotating cylindrical base as a substrate. A special lighting system exposes the individual layers, which then harden on the rotating drum. In this way, smooth, multilayer tubes containing complex material combinations can be created.

The researchers were able to prove the superiority of their method over traditional 3D printing processes in simulations and experimental tests. Processing of the hydrogels was also easy. In the next steps, scientists now want to improve the speed and accuracy of the PLLP technique.

Don't miss any other news!

We deliver the most important news and information on the topic of 3D printing to your inbox every week for free. Log in here. We are there too LinkedIn To exist. You can us Follow here!

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

The Council of Europe adopts the Artificial Intelligence Convention

Technology – The Council of Europe adopts the Artificial Intelligence Convention – Policy

Technology drives European stocks into the red, and doubts about interest rate cuts loom