Developing tomorrow's Swiss technologies is not something you learn in a lecture hall alone. So-called concentration projects are an integral part of the Bachelor's degree in Mechanical and Process Engineering at ETH.

Aspiring engineers work in teams to develop prototypes over the course of a year in order to demonstrate the current state of Swiss technology in the fields of additive manufacturing, robotics, driving and transportation technologies. Students go through the entire process independently – from idea development to design to finding sponsors and production.

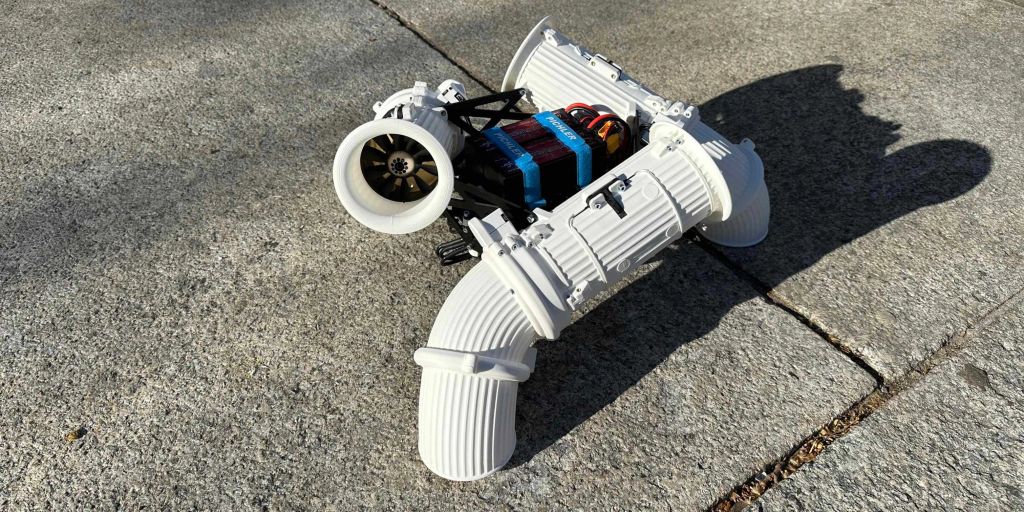

For example, ETH students developed the Avero safety inspection drone. The young engineers installed the propellers in tubes inside the drone. The resulting airflow is controlled by axial nozzles. This prevents injuries to people and damage to objects during operation.

The new motor offers more advantages: the drone can rotate to any position on two axes than conventional models and can fly closer to objects. Potential application areas include inspection tasks on difficult-to-access infrastructure and in congested environments such as construction sites.

Another project focus dealt with 3D printing. In additive manufacturing, machines apply materials layer by layer to produce components. This technology allows the construction of components with particularly precise and complex geometries.

In their project, the students developed a new robotic structure that can produce parts from two different metals. The fast, material-efficient process could be used, for example, in aerospace to reduce costs and improve rocket performance.

Upper body prosthetics are often very heavy. The goal of Sarah's project is to build a light, flexible robotic arm that can be further developed into a prosthetic limb. The students in the project team have a vision that prosthetic wearers will not feel the disadvantages of prosthetics in the future.

By developing the robotic arm, they want to pave the way for a new generation of lightweight, mobile and silent prosthetics. Instead of traditional motors, students use new robotic technology that mimics human muscle functions.

Actuators, that is, the elements that generate movement, consist of fluids in thin plastic membranes that convert electrical energy into mechanical energy. By incorporating artificial muscles into the prosthetic arm, students must make it more mobile and at the same time lighter.

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Technology – Dozens of WTO member states agree on global rules for online commerce

AI-powered traffic lights are now being tested in this city in Baden-Württemberg.

The use of artificial intelligence in companies has quadrupled