Lithium-ion batteries are used in mobile phones, e-bikes, and electric cars. In order for this to work, Openair plasma technology is used.

The basics in brief

- Not much is known about plasma, although 99 percent of visible matter is made up of plasma.

- Openair Plasma is an innovation for long-life lithium-ion batteries

- This technology was presented yesterday at the 5th Winterthur Adhesives Conference.

Compared with the traditional battery, lithium-ion battery has a higher energy density. It can store a lot of energy in a small space. This makes them particularly suitable for devices and vehicles that require powerful and compact energy storage.

But the service life of this battery is limited and it is a big challenge for us. And here comes the role of plasma. Klaus Kreisser, Managing Director of Plasmatreat Schweiz AG, presented the innovative Swiss technology at the Winterthur Adhesives Conference.

Swiss technology: plasma, an unknown substance

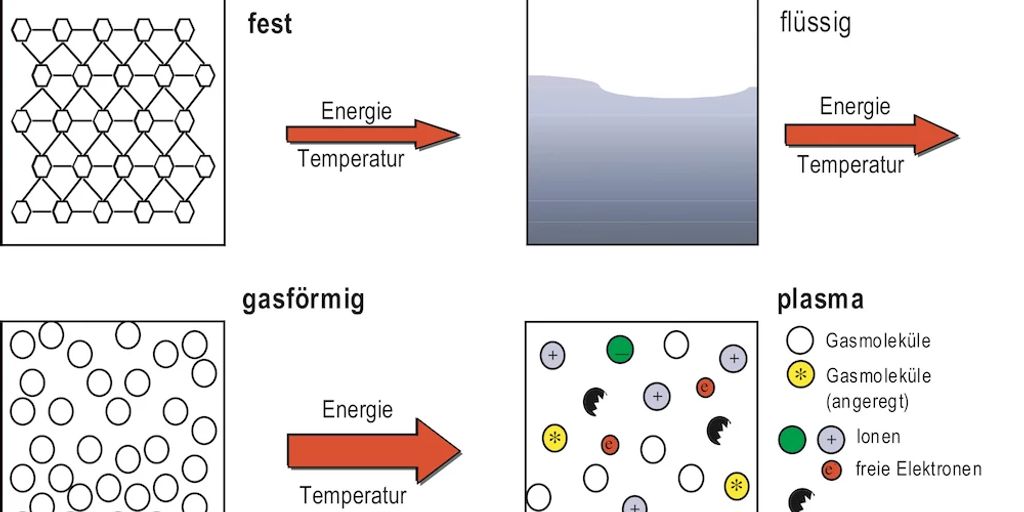

But what is plasma anyway? Plasma is the fourth state of matter, and it is an ionized gas consisting of positively and negatively charged particles. 99% of the visible matter in our universe is made up of plasma, including the aurora borealis and lightning.

But what is the state of matter? A state of aggregation is a physical state of a substance. The first three are solid (like ice), liquid (water) and gas (water vapor).

Less well known is the fact that plasma can also be produced artificially and has many different uses in industrial processes. For example, in order to paste, paint, print or paint, this multifunctional device is indispensable in many fields today.

Swiss technology: when the paint or film does not stick completely

An innovative technology has been developed to increase the quality of battery production: Openair Plasma. As the name suggests, this technology relies on the fourth physical state of matter, known as plasma. However, it is not a communication technology. Instead, it is used to pre-treat surfaces before gluing, foiling or, for example, sealing in battery applications.

Openair plasma technology is developed by Ing. Christian Buske, founder and managing director of Plasmatreat GmbH, based in Steinhagen, Germany. The Swiss subsidiary Plasmatreat Schweiz AG is headed by Managing Director Klaus Kreisser.

With plasma technology, challenges can be solved, particularly in the area of wetting, sealing and bonding in battery applications.

Electrical isolation of individual cells, such as prismatic cells, is one of the challenges. If the coating or foil does not adhere completely and evenly, there may be defects in the insulation. Plasma cleaning cleans the aluminum surface of the batteries. This allows a clean surface for the best possible adhesion of the paint or film.

Another challenge is ensuring thermal conductivity to prevent premature aging of batteries due to heat. This requires shorter drying times and specific surface energy requirements. Plasma curing can increase the surface energy to ensure optimal adhesion of the adhesive or coating.

Swiss technology: improves the lithium-ion battery

Lithium-ion battery consists of different components. It has a positive electrode made of lithium metal oxide and coated with aluminum foil. The negative electrode is made of graphite and applied to a copper foil. The electrolyte connecting the electrodes consists of a conductive salt dissolved in an anhydrous organic solvent.

A plastic spacer is placed between them so that the electrodes do not touch each other and cause a short circuit. To ensure a high-quality lithium-ion battery is clean, leak-proof and wettable, the battery interfaces are activated with Openair plasma. This process not only increases the production quality of the batteries. This also improves the performance and service life of the batteries.

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Samsung Quantum Dot TV: Art meets technology

Pitch: €56m for energy startup Reverion

Plastoplan: Plastics for Energy Transition