Francesco Perrone established a brewery in Vigevano, northern Italy, more than 175 years ago. Birra Peroni is now the most famous brand in Italy and is brewed in three locations: in Rome, Padua and Bari. First in Bari, Birra Peroni will soon use solar energy and significantly reduce the carbon footprint of its various beers and beers. The other two sites will follow suit if the first project proves successful.

Signing a heat supply contract

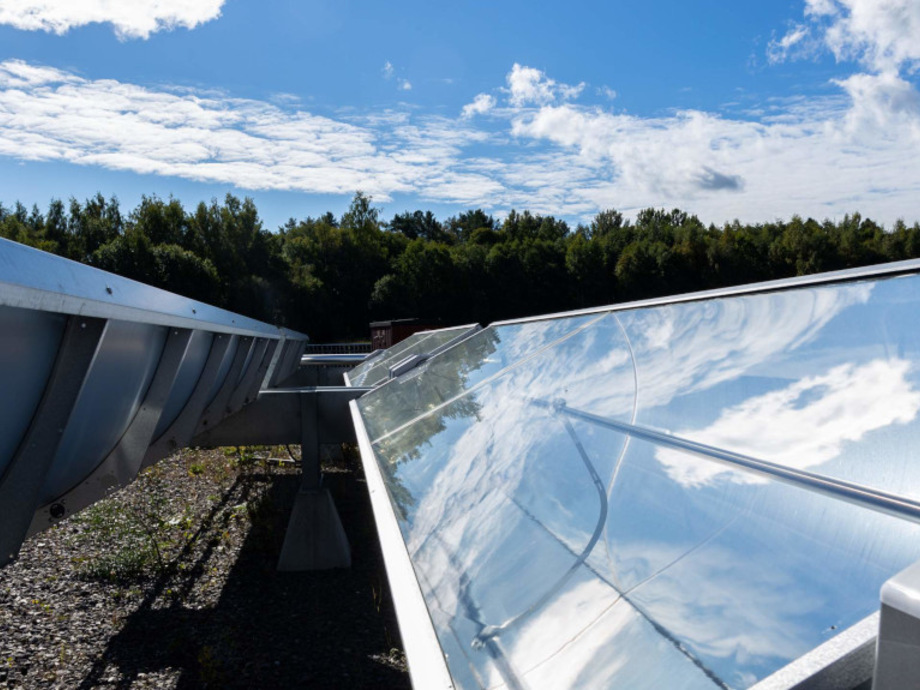

The brewery relies on solar thermal energy. Because one of the biggest energy consumption factors in a brewery is heat. That’s why Peroni wants to generate as much solar heat as possible. For this reason, Swedish supplier Absolicon will install the patented T160 solar collectors and integrate them into the brewery’s power system. Birra Peroni will then purchase the solar energy generated through a heat separation agreement to power the fermentation processes.

The temperature rises due to the concentration of sunlight

The advantage of Absolicon technology is that the collectors do not operate at lower temperatures like conventional solar thermal systems. Instead, the Swedes focus the captured sunlight onto integral tubes filled with heat transfer fluid, as in a small CSP power plant. This enables them to reach operating temperatures of up to 160°C. This heat can be used to generate steam at a pressure of eight bar. In this way, the collectors fully comply with the thermal energy requirements of the entire system and ensure the energy independence of the brewery operations supplied with solar heat. In addition, collectors track the path of the Sun on one axis. This means that there is plenty of solar heat available to the brewery throughout the day.

Climate-neutral fermentation by 2030

And so Pira Peroni takes a step towards decarbonization. “In line with our long-term sustainability goals, we have committed to making our production zero-emissions by 2030,” says Enrico Galasso, General Manager of Birra Peroni. He predicts that “the sustainability performance at our Bari plant is already on track and thanks to Absolicon technology, we will be approaching another big step towards our goal.” With the use of renewable heat, the brewery not only reduces carbon dioxide emissions, but also reduces costs and hedges against increased energy expenditures in the face of rising fossil fuel prices. The company avoids even investment costs through its contract agreement with Absolicon.

Do you want to stay updated on the energy transition? Then simply subscribe to the free newsletter from ERNEUERBARE ENERGIEN – Germany’s largest independent association magazine for renewable energies!

Gain operational experience

The system at the Bari plant is just the first step towards introducing solar heat into the Birra Peroni production process. After installation, the brewery wants to monitor how the solar system works for a year and gather relevant operating experience. Of course, the focus is on providing fossil fuels in the solar system without affecting the production process.

Planned another 12000 square meters of the complex area

If the experience is positive, the other two Birra Peroni plants will be equipped with Absolicon’s CSP technology. But the company assumes that the system works very well. Because the test period will be used to determine the general scope of other projects and to plan other systems with a scope of about 12,000 square metres. (see below)

This is also interesting for you:

4 demands for faster heat transfer

Study: Climate-neutral heat source possible by 2035

4 measures for faster expansion of solar thermal energy

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Samsung Quantum Dot TV: Art meets technology

Pitch: €56m for energy startup Reverion

Plastoplan: Plastics for Energy Transition