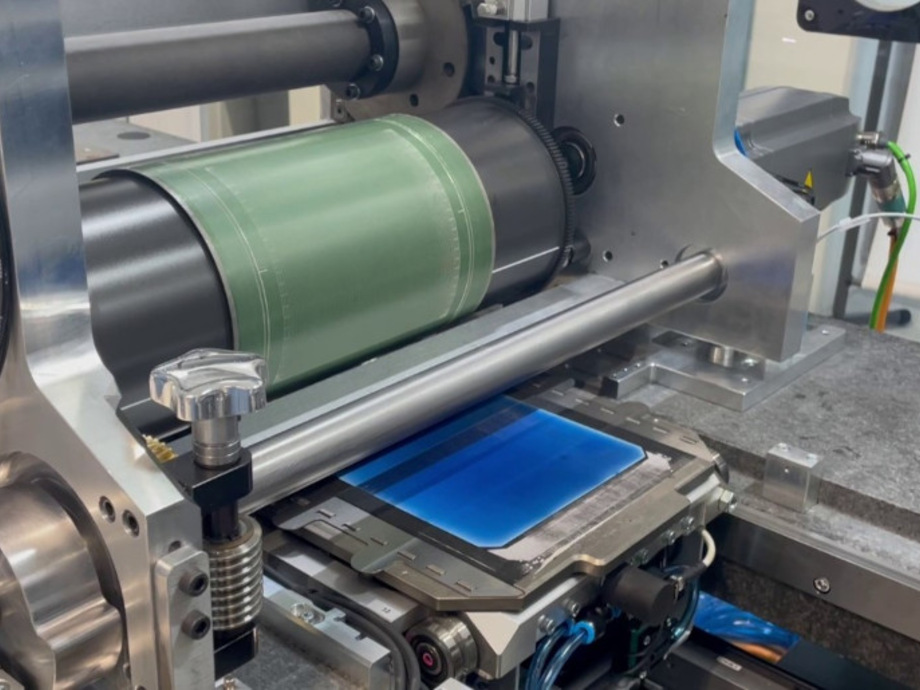

Together with Asys Automation Systems, Fraunhofer ISE has developed a new production system that can be used to produce solar cells 1.5 times faster. The central innovation is solar cell mining. Because the rods and grids of cells are applied to the solar cell by screen printing. In the new line, the developers replaced the previously common flat screen printing process with rotary screen printing and flexographic printing process.

0.6 seconds per cell

With the new system, developers and researchers were able to mine solar cells in a time cycle of just 0.6 seconds per cell. “Due to this process, metal processing using screen printing is currently limited to a throughput of about 0.9 seconds per solar cell and path,” says Florian Clement, Head of Production Technology – Structuring and Mining at Fraunhofer ISE, compared to the previous process. “So printing is a bottleneck in the production process of silicon solar cells, as well as in the process of coating general charging components in many other sectors,” he explains, outlining other possible applications. Because rotary screen printing is also suitable to metal other electronic components used in power electronics, among other things.

Meticulously laminated

In order to achieve the target printing speed, the researchers along with Swiss machine maker Gallus Ferd. Rüesch, a subsidiary of Heidelberger Druckmaschinen), has developed a new high-throughput transmission system. The chips are placed in so-called shuttles and moved through the system with high speed and accuracy, while being delicately encased in the finest structures.

Do you want to stay updated on the energy transition? Then simply subscribe to the free newsletter from ERNEUERBARE ENERGIEN – Germany’s largest independent association magazine for renewable energies!

double throughput

However, the new system so far is just evidence showing that the technology also works with solar cells. And with this concept, they have already been able to demonstrate their ability to significantly speed up the printing process. “The system has the technical potential to double the productivity compared to screen printing systems,” says Andreas Lorenz, project manager at Fraunhofer ISE.

This is also interesting for you:

Fraunhofer and Rielling produce PERC solar cells from recycled silicon

Five innovations in battery technology

Detlef Neuhaus from Solarwatt: ‘We are already thinking about the next product line’

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Samsung Quantum Dot TV: Art meets technology

Pitch: €56m for energy startup Reverion

Plastoplan: Plastics for Energy Transition