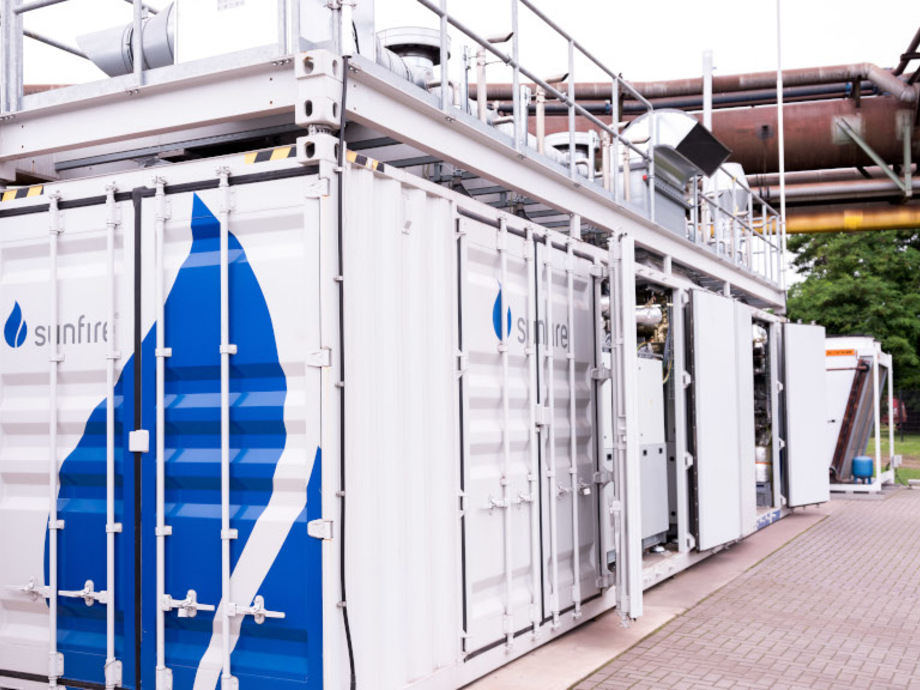

Sunfire has installed a high-temperature electrolyzer at its Salzgitter AG steel mill, which is now proven to be 84 percent efficient. The electrolyzer itself is based on the well-known principle of SOEC technology, according to which water is split into its components hydrogen and oxygen with the help of excess green electricity.

High efficiency in megawatts

However, Sunfire achieves a high level of efficiency because electrolysis occurs at a high temperature. “The system operates at operating temperatures of 850°C,” explains Konstantin Schwartz, Product Manager for Large Electrolysis Systems at Sunfire. This high temperature, in turn, is provided by steam, which is obtained from the waste heat that accumulates during the production of steel in Salzgitter AG. “This is why our electrolyzer requires much less electricity than conventional techniques to produce large amounts of green hydrogen,” says Konstantin Schwartz. As part of the project, Sunfire was able to demonstrate high efficiency at 84 percent on the megawatt scale. For comparison: Current technologies such as alkaline electrolysis and PEM achieve efficiencies of around 60 percent.

Do you want to stay updated on the energy transition? Then simply subscribe to the free newsletter from ERNEUERBARE ENERGIEN – Germany’s largest independent association magazine for renewable energies!

400 cubic meters of hydrogen per hour

The plant is built in Salzgitter AG as part of the Salcos (Salzgitter Low CO2 Steelmaking) project, through which the steel manufacturer aims to reduce greenhouse gas emissions in production by 2030. The electrolyzer is capable of producing 400 standard cubic meters of hydrogen per hour, Which is directly used in steel production. This high level of efficiency is a real step forward for Salzgitter AG. “The scarce resource of electricity from renewable sources is ideally used here to produce hydrogen and it is another step towards green steel production,” stresses Stefan Mieke, Salcos project spokesperson within Salzgitter AG. (see below)

This is also interesting for you:

Polarstern and SWE use solar and wind energy to produce domestic hydrogen

H2 plant for Hollandse Kust Noord

Trianel and Stadtwerk Hamm established a joint hydrogen center

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Pitch: €56m for energy startup Reverion

Plastoplan: Plastics for Energy Transition

Canon Launches Arizona 1300 Series with FLXflow Technology