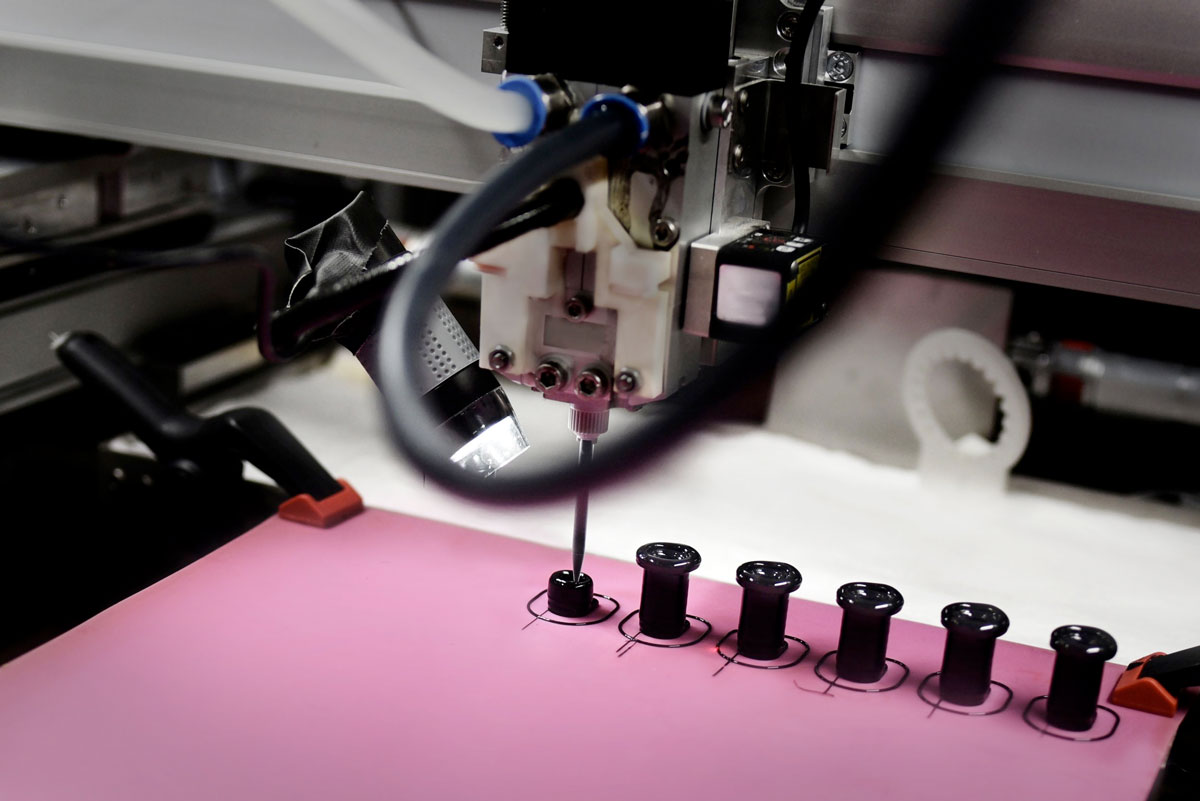

Chromatic 3D Materials, a 3D printing technology provider, has developed advanced Smooth Mode technology for 3D printing of durable, ultra-smooth surface rubber parts in commercial quantities. Industrial manufacturers can now 3D print smooth, high-quality polyurethane parts such as gaskets, gaskets, o-rings, bladders and other flexible products without post-treatment or surface treatment.

“Shims require a smooth surface, but 3D-printed parts almost always have streaks or bumps. We’ve created a way to easily and inexpensively print ultra-smooth products with no extra steps,” says Dr. Cora Liebig, CEO and founder of Chromatic.

Smooth Mode printed parts have better aesthetics and dimensional accuracy. For example, products can be printed with accurate and uniform thickness in the millimeter range. Therefore, the new technology is suitable for the production of rubber bags and other flexible products that expand and contract.

Chromatic’s team of additive manufacturing experts first achieve ultra-smooth prints by adjusting the viscosity and surface tension of the company’s printable thermoplastic polyurethane materials.

“We have developed a method that goes beyond simply applying our reaction technology to FDM printing. Smooth mode uses chemistry to create a highly bonded and seamless part. We believe this printing technology enables the world’s smoothest printing along the Z axis or elevation axis,” explains Dr. Bart Engendal, Managing Director of Chromatic Germany.

Industrial manufacturers can take advantage of a seamless mode with Chromatic’s RX-AM materials and technology platform. RX-AM is a 3-in-1 platform that includes materials, software, and hardware for reactive chemistry precipitation printing. RX-AM (Reactive Extrusion Material Manufacturing) uses printable polyurethane with Shore A hardness from 50 to 90, as well as custom grades of different colours, hardness and special properties (eg, anti-bacterial, static discharge, biocides, etc.). The platform is designed to print commercial quantities.

Find out more about Chromatic over here.

Don’t miss any other news!

We bring the most important news and information on the topic of 3D printing to your inbox every week for free. Register here.

“Certified tv guru. Reader. Professional writer. Avid introvert. Extreme pop culture buff.”

More Stories

Classic espionage, cyber attacks, creating economic dependencies, and technology withdrawal –

How the technology behind ChatGPT powers this bot

Mercedes G580 with EQ technology: The G-Class has become electric